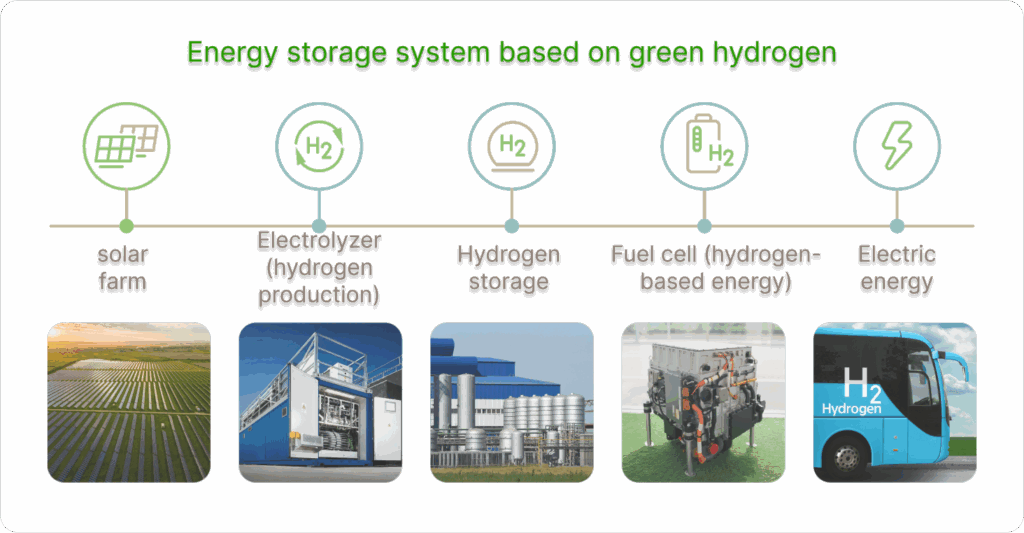

green hydrogen

Green Hydrogen

fuel of the future

Supplying highly efficient hydrogen production devices is currently a challenge in Europe and worldwide. GreenTop Energy has chosen anion exchange membrane (AEM) electrolyzer technology, which we consider the “dark horse” in green hydrogen production. this technology combines the advantages of alkaline (AL) electrolyzers – cost and safety – with those of PEM electrolyzers – efficiency and operational flexibility. additionally, the AEM electrolyzer does not use conflict metals in its operation, making its cost competitive and the technology independent of factors related to specific national resource policies and global supply chains. the use of AEM electrolyzers also gives us a competitive advantage in the form of lower costs compared to other technologies.

Main advantages of energy storage in the form of hydrogen:

- Wodór pozwala magazynować dużo energii w małej objętości, znacząco przewyższając możliwości tradycyjnych akumulatorów, co czyni go szczególnie przydatnym do długoterminowego i sezonowego przechowywania.

- Hydrogen enables the accumulation of energy surpluses during periods of high production, e.g., summer solar generation, and their use during periods of increased demand or low production, e.g., winter,

- Storing energy in the form of hydrogen allows the use of zero-emission fuel. when burned or used in a fuel cell, it produces only water, with no CO₂ or other chemical emissions such as NOx, SOx, etc.

- Hydrogen can be used both for electricity and heat production, as well as a raw material in industry or as a fuel in transport.

- Hydrogen storage systems promote energy self-sufficiency for households and communities, reducing dependence on external energy suppliers and increasing resilience to market fluctuations.

- Hydrogen loses virtually no energy during long-term storage, which is an advantage over batteries that gradually lose stored energy; hydrogen can be stored with minimal losses for up to 12 months.

- Modern hydrogen storage systems are designed with high safety standards and can be scaled from small home installations to large industrial storage facilities.

Hydrogen-based energy storage systems are ready for immediate operation without the need for long start-up times.

Inwestycja GREENTOP ENERGY

1

Construction of a pilot installation comprising a 1 MW AEM electrolyzer, supporting infrastructure, fuel cells, and a hydrogen refueling station. The hydrogen produced in this installation will be supplied for public transport—buses equipped with fuel cells. We anticipate signing a fuel off-take contract for 10–15 years.

2

The next stage will be the construction of a factory for AEM electrolyzers and fuel cells. This will be the first production of its kind in Poland and the third in Europe. We are currently carrying out administrative procedures with the Radwanice municipality to obtain the necessary permits for both investments.

3

We plan to sell the electrolyzers we produce to interested customers across Europe. To this end, we have begun actively seeking clients and compiling an order book.

4

Launching the first large-scale fuel cell assembly plant in Poland, serving the European fuel cell market. The choice of location for this project is also deliberate: we are implementing it near the KGHM corporation, which is potentially the largest consumer of fuel cells.

5

Micoled Sp. z o.o., a holding company, has developed an innovative and globally competitive power supply for electrolyzers, for the construction of which it secured funding from the Lower Silesian Regional Operational Programme (RPO Dolnośląskie). The device is intended for electrolyzer manufacturers and suppliers, regardless of hydrogen production technology.

6

At the same time, we plan to start hydrogen production for energy storage and injection into the grid. This project has been submitted to the strategic plans of Gaz System SA.

Delivering highly efficient hydrogen production devices is currently a challenge in Europe and worldwide. GreenTop Energy has chosen the anion exchange membrane (AEM) electrolyzer technology, which we consider the “dark horse” in green hydrogen production. This technology combines the advantages of alkaline (AL) electrolyzers—cost and safety—with those of PEM electrolyzers—efficiency and operational flexibility. Additionally, the AEM electrolyzer does not rely on conflict metals, making it cost-competitive and independent of factors related to specific national resource policies and global supply chains. Using an AEM electrolyzer also provides us with a competitive edge in the form of lower prices compared to other technologies.